When Michael Elmasry arrived in Australia in the early 1990s, he brought with him more than just a structural engineering qualification—he brought a vision. One that would go on to reshape the steel detailing landscape in New South Wales and beyond.

Michael Elmasry, Managing Director of Elmasry Steel Design and Detailing, established the business in 1994 after recognising a gap in the Australian market. “When I started working as a project manager for a steel fabricator, it became clear that the local industry was crying out for better quality steel detailing,” he recalled. “There were too many mistakes in shop drawings, and it was costing time and money. My boss asked me to start in-house detailing, and from there, the idea grew.”

Today, Elmasry Steel Design and Detailing is a cornerstone of the structural steel sector. From its humble beginnings as a one-person operation, it quickly scaled to become Sydney’s largest steel detailing office within five years—a position it has maintained through a combination of technical innovation, client focus, and a steadfast commitment to quality.

Pioneers in technology

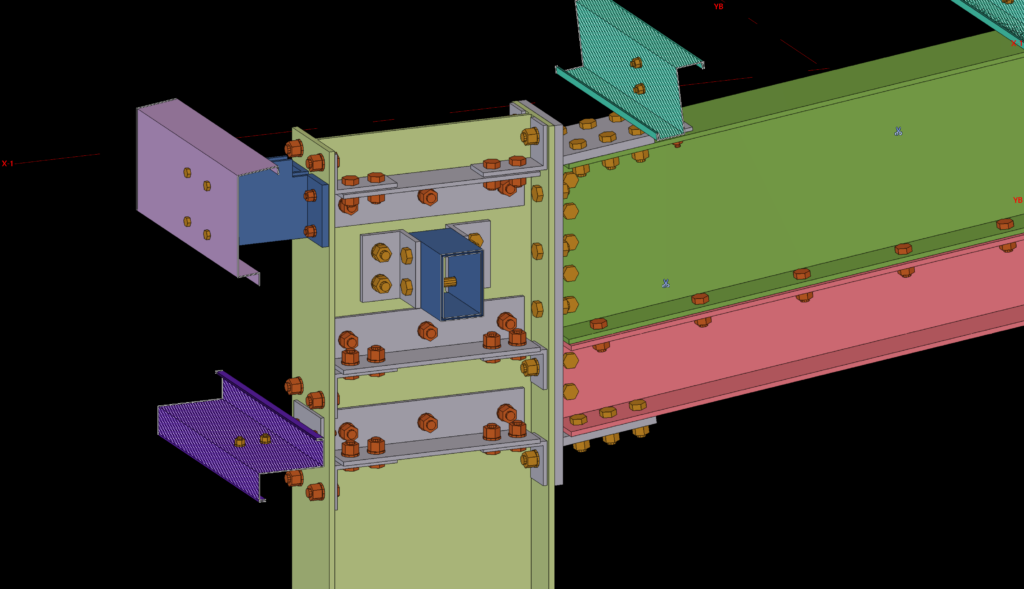

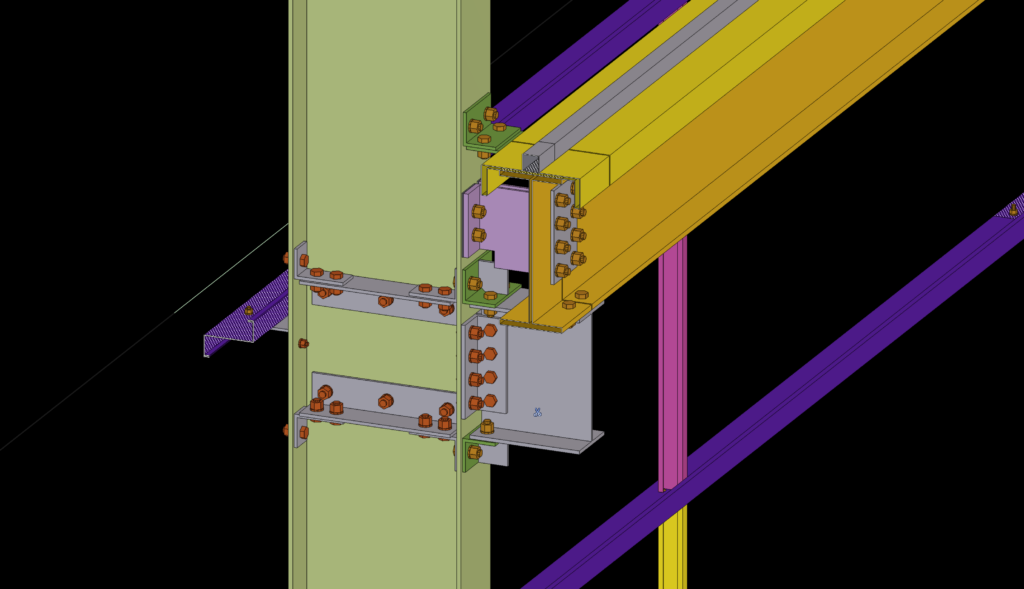

The company was ahead of the curve in adopting 3D modelling technology, a move that set it apart from competitors. “We began using Tekla Structures back in 1996—long before most others had even heard of it,” said Elmasry. “For over 25 years now, we’ve been the largest Tekla user in New South Wales, and we’ve completed over 1,360 projects using this platform.”

The adoption of Tekla allowed the business to provide highly accurate, clash-free, and fabrication-ready shop drawings. It also enabled a seamless transition from design to detailing, reducing rework and eliminating delays. Elmasry’s team is known for its ability to collaborate effectively across disciplines using Building Information Modelling (BIM)—a capability that continues to deliver real-time efficiencies and savings across projects.

From detailing to design

While steel detailing remains the core of the business, the company’s ability to offer integrated structural design services has set it further apart. “In Australia, the typical process is that the structural engineer finishes their documentation first, then the detailing starts. It’s like doing the work twice,” Elmasry explained. “So, we decided to offer both design and detailing as one package.”

“Steel detailing is a critical and foundational aspect of the construction and engineering industry, serving as the essential bridge between the conceptual design and the actual fabrication of steel components. Its primary function is translating architectural and structural plans into detailed, actionable instructions that guide the entire steel construction process. Without precise detailing, the execution of the structural framework of a building or infrastructure project can be compromised, leading to significant safety risks, inefficiencies, and financial loss.”

By combining structural analysis software with Tekla Structures, Elmasry’s team is able to create a single, integrated model for both design and detailing. This approach reduces project timelines and ensures that detailing is informed by a deeper engineering understanding. “We can move freely between analysis and detailing software, which saves our clients time and money,” he said.

A track record of excellence

Elmasry’s project portfolio is as broad as it is impressive. The company has delivered structural steel detailing and design across nearly every sector of construction, from power stations and petrochemical plants to hospitals, schools, and major public infrastructure.

Some standout projects include the Sydney Modern Project at the Art Gallery of NSW, Parramatta Stadium, the Crown Casino at Barangaroo, the Sydney Metro Martin Place – North Tower, and the Western Sydney International Airport Terminal. In each case, Elmasry’s contributions have played a pivotal role in ensuring the success of complex, high-profile builds.

“One project that stands out is the Sydney Metro Martin Place North Tower,” said Elmasry. “The geometry at the top of the tower is incredibly complex. Our detailing had a direct impact on how the design evolved. It’s a great example of how our expertise adds real value to the entire project lifecycle.”

Quality through people

At the heart of the company’s success is its team. Unlike many in the industry, Elmasry insists on hiring qualified professionals—most of the firm’s detailers hold degrees in civil or structural engineering.

“There are no formal qualifications required for shop detailers in Australia, which I believe is a problem,” he said. “We only employ high-calibre people. The software we use is incredibly powerful, but it needs skilled operators.”

The company’s collaborative, problem-solving culture is another key to its longevity. “We don’t complain—we overcome challenges,” said Elmasry. “If we see an issue with a connection, we don’t just send an RFI. We propose a solution. That saves time and helps everyone on the job.”

Facing industry challenges

Despite Elmasry’s success, he remains deeply concerned about the broader challenges facing the Australian steel industry—particularly the rise in offshore fabrication and detailing.

“Too many projects are being sent overseas, even government ones,” he says. “But when you look at it closely, projects done here—using smarter, more efficient detailing and bolted connections instead of welding—can actually compete on cost.”

Elmasry is a vocal advocate for keeping more manufacturing and fabrication jobs in Australia. “We need to think long-term. If we want to reduce emissions, support local industries, and build a sustainable economy, then we should be fabricating mining equipment, wind turbines, and infrastructure here, not overseas.”

He believes the solution lies in a combination of smarter engineering, greater use of bolted rather than welded connections, and long-term investment in affordable energy sources like nuclear. “Welding is expensive, time-consuming, and not great for the

He believes the solution lies in a combination of smarter engineering, greater use of bolted rather than welded connections, and long-term investment in affordable energy sources like nuclear. “Welding is expensive, time-consuming, and not great for the environment,” he noted. “Bolted connections reduce cost and errors—and that can make the difference in keeping work in Australia.”

Building for the future

Looking ahead, Elmasry remains optimistic—provided the industry is willing to evolve. “We need to work smarter, not harder,” he said. “That means using technology better, upskilling our workforce, and making sure the next generation understands the importance of quality in steel detailing.”

With its innovative use of technology, dedication to client success, and commitment to raising industry standards, Elmasry Steel Design and Detailing is well-positioned to lead that charge.

“The importance of steel detailing extends far beyond the drawing board. Skilled steel detailers are integral to the construction process because their work directly influences the efficiency, cost-effectiveness, and quality of the final project. Without their expertise, the entire process—from design to fabrication to erection—would be fraught with errors and inefficiencies, jeopardizing both safety and financial outcomes. As the complexity of construction projects continues to rise and the demand for precision increases, the role of steel detailing becomes even more indispensable in ensuring that structural frameworks are built to last.”

“Ultimately, our mission is simple,” said Elmasry. “To deliver shop drawings of the highest quality—and to help our clients succeed. Their success is our success.”